L R AS Published on Sunday 17 May 2020 - n° 322 - Categories:panels, various sectors

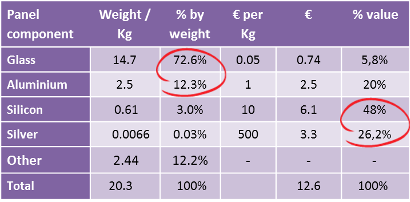

Components of old panels (weight-value)

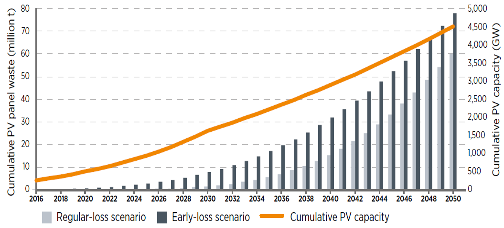

The development of solar installations heralds a growing volume of panels at the end of their life. Hence recycling. The forecast for end-of-life panels could reach

1.7 to 8 million tonnes in 2030 in the world (Editor's note: The forecast deviation is to be admired. This one does not seem very reliable because we do not know the lifespan of the panels which was retained: 20 years ? 25 years ? 30 years?)

The European directive requires 85% of the panels to be collected and 80% of the materials composing the panels to be recycled. However, 80% of the weight is made up of the aluminium frame and the front window. However, 80% of a panel's value comes from the components used to manufacture solar cells, in particular silicon, copper and silver. The difficulty lies in the delamination of the material "sandwich" which forms the main body and from which valuable materials can be recovered. The main obstacle to delamination is posed by the degradation of the encapsulating polymer, usually ethylene vinyl acetate (EVA).

The most common recovery methods are mechanical. They involve cutting, crushing and screening. These processes are already deployed on an industrial scale. Some companies focus solely on the recovery of specific materials from dead panels, such as glass. The National Institute of Solar Energy (Ines) is developing a new approach to mechanical cutting to recover high-purity glass, plastics and metals. Recycling is set to expand rapidly in the near future, focusing on recyclability and environmental footprint,

https://www.pv-magazine.com/2020/05/13/pv-module-recyclers-aiming-for-high-purity-material-recovery/

PV Magazine of 13 May